Design & Sampling

Custom plush toy sampling plays a critical role in turning design ideas into approved, production-ready products. This page explains how we approach plush toy samples and prototypes, and why a structured sampling process matters before any production decisions are made.

Why Sampling Matters in Custom Plush Toy Projects

In custom plush toy development, sampling is not a formality — it is the stage where ideas become measurable, reviewable, and controllable.

For gift brands, pet product companies, and promotional buyers, plush toy sampling helps reduce uncertainty long before production begins.

A physical plush toy sample or prototype allows you to evaluate proportions, materials, construction, and overall feasibility. More importantly, it helps identify potential risks early during the plush sampling process, before timelines and budgets are committed at scale.

How We Manage the Design & Sampling Process

As a custom plush toy manufacturing partner, we directly manage the custom plush toy sampling stage to ensure clarity, consistency, and alignment with your project goals.

Our role focuses on:

- Clarifying requirements at the earliest design stage

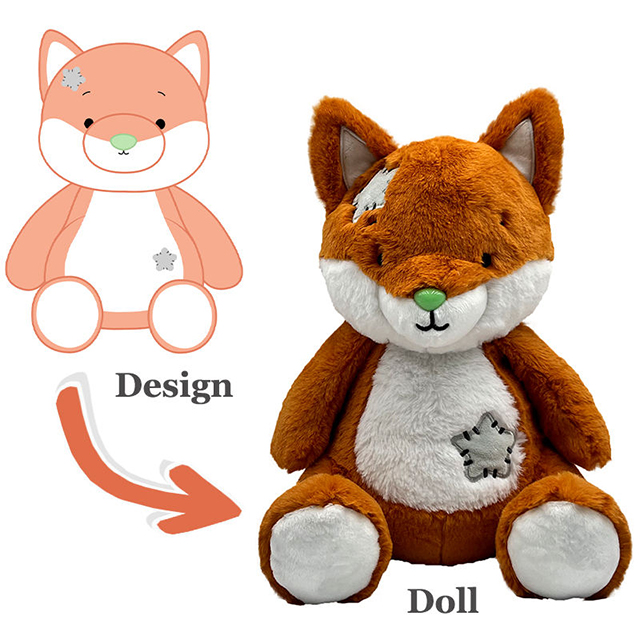

- Translating concepts into workable plush toy prototypes

- Managing communication throughout the plush sampling process

We coordinate with manufacturing partners to support custom plush toy design decisions, including materials, craft execution, and packaging considerations during sampling. While production resources may vary by project, the sampling workflow itself is centrally managed and carefully reviewed.

From Concept to Sample: Key Checkpoints We Focus On

Rather than treating sampling as a single action, we focus on key checkpoints within the plush toy design process that determine whether a concept is ready to move forward.

These checkpoints typically include:

- Proportion and size accuracy, especially for character or branded designs

- Fabric selection and hand feel, aligned with the intended use

- Structural integrity, including seams and attachments

- Visual consistency, ensuring the sample reflects original design references

- Production feasibility, assessed during plush toy development

By reviewing each plush toy prototype against these criteria, potential issues can be addressed before production planning begins.

Material, Craft & Packaging Decisions During Sampling

Material and craft choices influence both the appearance and performance of a plush toy. During sampling, we support material selection and coordinate craft options based on specific project requirements.

Packaging considerations are also reviewed during the sampling stage. Plush toy packaging design, labeling concepts, and presentation formats can be evaluated alongside the product sample, helping ensure consistency between the product and its final presentation.

Sample Approval Before Production

Plush toy sample approval is a critical checkpoint before any production arrangements are confirmed.

An approved plush toy prototype serves as the reference standard for size, construction, materials, and finishing details.

Confirming these elements at the sampling stage helps:

- Reduce misunderstandings during production

- Establish clear expectations for manufacturing partners

- Create a consistent reference for quality checks

While no process eliminates every variable, structured sample approval significantly improves predictability.

How This Process Supports Gift & Pet Plush Projects

Sampling is particularly important for gift and pet plush toy projects.

Gift Plush

For gift plush toy samples, visual accuracy, branding alignment, and presentation quality are essential. Sampling helps ensure these details are reviewed before launch.

Pet Plush

For pet plush toy prototypes, structure, durability, and material suitability require closer evaluation. Sampling allows these aspects to be assessed early, supporting safer and more reliable product outcomes.

Standard plush designs follow a similar approach, but gift and pet projects often require additional attention during the sampling stage.

Next Steps: Moving from Sample to Production

Once the plush sampling process is completed and the sample is approved, the project can move forward with greater confidence.

At this point, production planning, quality checkpoints, and delivery schedules can be discussed in detail.

If you are currently reviewing a plush toy sample or planning a new custom project, the next step is to confirm design requirements and sampling expectations before proceeding further.

You may explore:

Our production workflow

Sample and product showcases

Or contact us to discuss your project scope