Introduction

When buyers ask about plush toy pricing, the real challenge is rarely the number itself.

The difficulty lies in understanding what actually drives the cost, and which variables are adjustable without compromising the project outcome.

In this article, we break down how plush toy pricing is formed from a buyer’s perspective—based on real custom plush samples experience, process control, and cost trade-offs we see across different custom projects.

Size and Structural Complexity

Why size alone is not the full story

Larger plush toys naturally consume more material, but structure complexity matters more than dimensions.

Multiple panels, internal layers, or shaped limbs increase cutting and stitching time.

Two finished plush examples toys of the same height can differ significantly in cost if one requires more pattern pieces or reinforced joints.

Material and Filling Selection

Fabric grade affects both cost and consistency

Fabric choice impacts pricing beyond the surface feel.

Higher-grade plush fabrics offer better color stability, durability, and lower defect rates—but come at a higher unit cost.

Filling materials also vary in density and resilience. Cheaper filling may reduce upfront cost but often leads to deformation issues during inspection or shipping.

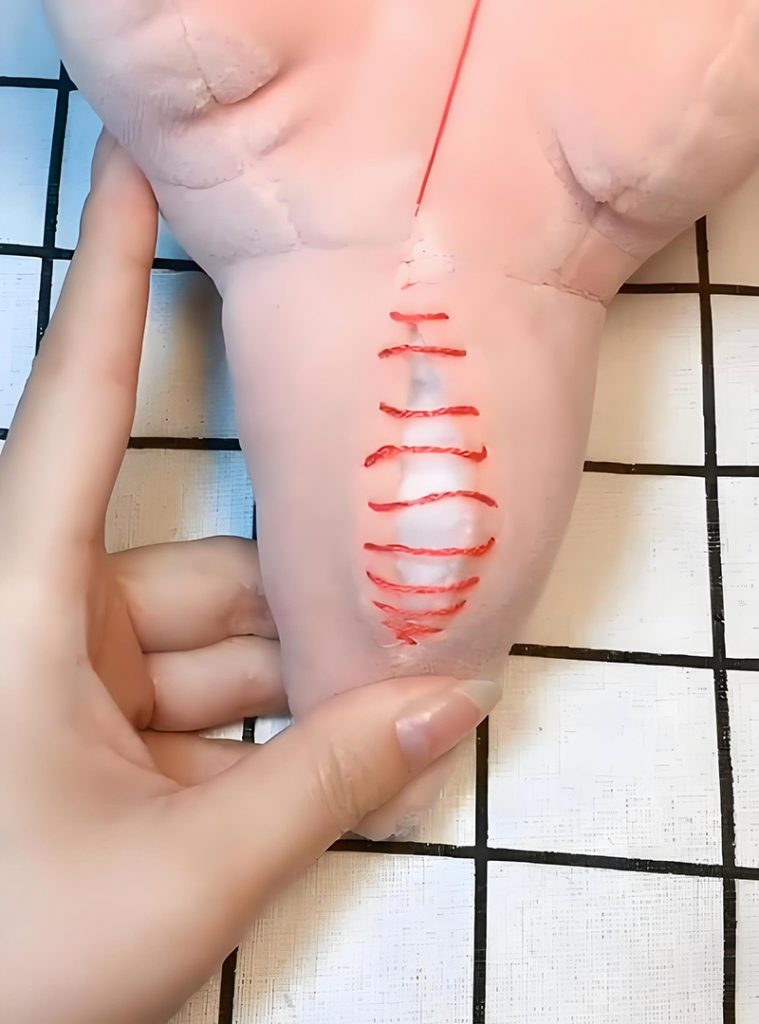

Embroidery and Detail Density

Small details add measurable labor time

Embroidery, appliqué, and facial detailing are often underestimated cost drivers.

Dense stitching or multi-color embroidery increases machine time and raises the likelihood of sample adjustments.

From a pricing standpoint, detail density matters more than decoration type.

Sampling and Revision Cycles

Sampling cost is part of total project cost

Sampling and control process is not just a prototype—it’s a cost-control phase.

Each revision involves pattern adjustments, material usage, and time.

Projects with clear specifications typically stabilize faster, while vague briefs tend to accumulate hidden costs through multiple sample rounds.

Order Quantity and MOQ Thresholds

Unit cost changes once MOQ is crossed

MOQ is not a sales tactic—it reflects cost efficiency thresholds.

Below MOQ, fixed setup and handling costs are spread across fewer units, pushing unit prices up.

Once a project reaches a stable quantity, pricing becomes more predictable and easier to optimize.

For specific details, you can get answers by initiating a project inquiry.

Quality Control and Inspection Scope

Inspection standards influence real cost

Quality control affects pricing through rejection rates and rework.

Stricter inspection standards require more handling time but reduce post-delivery risks.

Buyers should evaluate whether inspection scope aligns with product positioning and distribution channel.

Packaging and Compliance Requirements

Packaging is often the final cost surprise

Custom packaging, labeling, and market compliance (such as safety labeling) add material and labor layers.

These costs are typically fixed per unit and should be considered early—especially for retail or promotional distribution.

Who This Cost Structure Fits — and Who It Doesn’t

Suitable for:

Brands planning repeat or scalable plush toy programs

Buyers who value sample accuracy and predictable quality

Projects with defined specifications and timelines

Not suitable for:

One-off orders with extreme customization and low volume

Buyers seeking the lowest possible unit price without cost transparency

FAQ: Plush Toy Pricing Questions Buyers Ask

- Why do similar plush toys have different prices?

Because material grade, structure, and detail density vary beyond appearance. - Does larger size always mean higher cost?

Not always—complexity often outweighs size. - Are sampling costs refundable?

Sampling costs are typically separate due to material and labor investment. - How many sample rounds are normal?

Most stable projects finalize within one to two revisions. - Can materials be adjusted to meet budget?

Yes, but changes should be evaluated for durability and consistency. - What affects MOQ the most?

Setup cost, material sourcing, and handling efficiency. - Is quality inspection optional?

Inspection scope can be adjusted, but removing it increases risk. - Does custom packaging affect lead time?

Yes, packaging design and sourcing add additional coordination time.