Your Reliable Partner for Custom Plush Development

As a leading plush toy manufacturer in China, we offer full OEM/ODM custom plush toys, from fabric selection and component sourcing to sampling, mass production, and global delivery.

Custom Plush Toy Service Advantages

Anything you envision can be developed with precision.

With our specialization in structured plush development, we help brands and sourcing teams turn concepts into production-ready plush products. From technical patterns to material planning and scalable manufacturing, every part of our service is built to support reliable, repeatable, and market-focused plush creation.

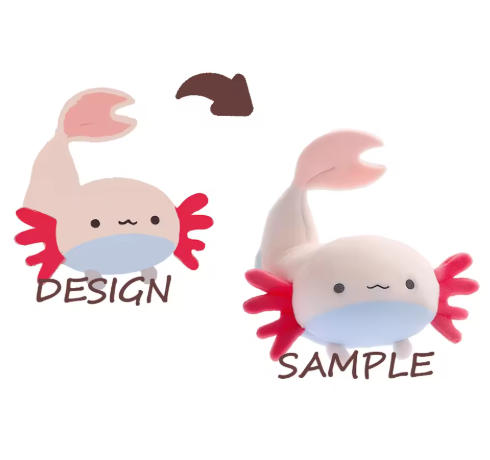

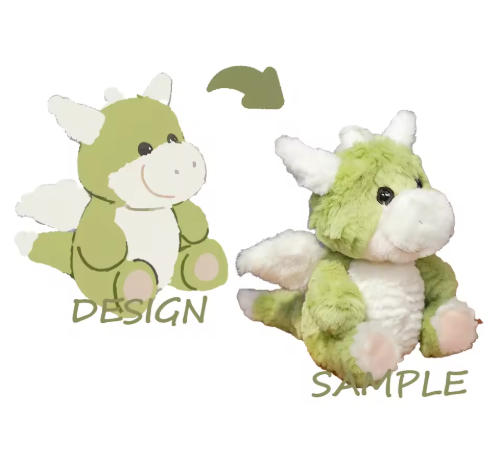

Accurate Pattern Translation

Our technical developers focus on converting your artwork into clean, production-ready patterns, ensuring your plush model keeps its intended proportions and character details.

Efficient Sampling & Development Support

Our structured sampling system helps shorten development time with clear communication on fabrics, dimensions, and adjustments, ensuring your prototype moves smoothly into production.

Flexible Order Structures

Start with quantities ideal for testing new concepts, validating prototypes, or launching seasonal or small-batch collections.

Consistent Quality Assurance

Each plush item undergoes multi-stage inspections, covering stitching strength, stuffing balance, fabric condition, and safety components before packaging.

Advanced Material Adaptation

We help you select and adapt suitable plush textiles to achieve the desired softness, durability, and visual finish across different product categories.

International Safety Standards Compliance

Our custom plush projects meet major global toy safety standards—including EN71, ASTM F963, CPSIA, REACH, and ISO 8124—to ensure full market compliance.

Customizable Packaging Options

From wash labels and woven tags to branded retail packaging, every detail can be tailored to enhance your product’s market presentation.

Multiple Logistics Solutions

Choose from full-container, LCL consolidation, or express courier options to match your delivery schedule and shipment size.

Commonly Used Plush Fabrics

As part of our professional plush development service, we select materials based on texture, durability, and suitability for different plush applications. With access to a wide range of industry-standard fabrics, we help you identify the most practical and production-ready options for your custom plush project.

Crystal Super Soft (Short Plush)

Crystal Super Soft is known for its smooth, delicate touch and short fiber length ranging from 1–5mm. This fabric offers good color uniformity, stable surface texture, and a high degree of softness, making it ideal for plush toys that require clean lines or simple shapes. Slimmer variants create a sleek appearance, while thicker versions add more visual volume.

PV Plush (Long Pile Plush)

PV Plush features longer fibers (5–50mm), rich colors, and a soft, dense texture suitable for medium- to large-size plush designs. Available in matte or semi-gloss finishes, this fabric maintains shape well and is commonly used for animal-themed plush and expressive characters requiring fuller volume.

Rabbit Velvet (Yutu Plush)

Rabbit Velvet is a soft, fine-fiber fabric with a gentle skin-like feel and a pile height of around 5mm. It offers a smooth, consistent sheen and is a popular choice for trendy plush products, keychains, and small plush lines that require a premium hand-feel without excessive fluff.

Spandex Super Soft (Elastic Plush)

Elastic Plush combines spandex fibers with a soft surface, offering excellent stretch recovery and resistance to wrinkling or deformation. This fabric is commonly used for plush cushions, stress-relief toys, and shapes requiring flexibility while maintaining structural integrity.

European Mink (High–Low Pile)

European Mink, also known as Snow Mink or Jade Fox Plush, blends natural and synthetic fibers to achieve a soft, luxurious texture. Its high–low pile surface brings plush characters to life with depth and visual dimension, making it suitable for premium plush lines and high-end collectible designs.

Pearl Plush

Pearl Plush stands out with its compact, bead-like surface and excellent resilience. It offers a smooth texture that works particularly well for short-fur animals, mascots, and character plush designs. Its stable structure makes it a reliable material for maintaining shape consistency.

How to Choose the Right Plush Fabric

Selecting the right fabric is a key step in ensuring your custom plush looks and performs as intended. Below are practical methods we recommend to help you make informed decisions during development.

1. Explore Local Stores or Existing Products

Visiting local toy or fabric shops can help you assess texture, density, and color in person. This is an effective way to build your initial preference list if you’re developing a new plush line.

2. Provide Samples or References

If you already have a sample plush or fabric swatch, share it with us. We will match it with the closest available options from our network of material suppliers. If you only have design sketches, we’ll recommend appropriate swatches based on usage and manufacturing feasibility.

3. Use Different Fabrics for Different Parts

Many plush toys require a mix of fabrics—short plush for the body, long plush for hair, and velvet options for facial areas. We’ll review your design and confirm all fabrics before sampling to ensure consistency and practicality throughout production.

4. Understand Fabric Quality Essentials

GSM (fabric weight), pile direction, shedding resistance, and elasticity all affect the final outcome. Higher GSM fabrics provide better durability, while premium long-pile materials offer improved softness and visual appeal.

Frequently Used Plush Accessories

In custom plush production, choosing the right accessories is essential for achieving accurate expression, safe construction, and strong visual appeal. This section presents commonly applied components that enhance functionality and reinforce the final look of your plush design. Each accessory category below is selected based on practicality, safety, and compatibility with mass production.

Plastic Eyes

Plastic eyes come in various types—including safety eyes, 3D printed eyes, cartoon styles, matte eyes, glossy eyes, and animal-specific versions. Selecting the right eye style significantly influences character expression. When developing your design, we provide guidance to match eye type, size, and fastening structure to your plush pattern.

Plastic Noses

Plastic noses range from rounded, embossed, and matte finishes to more detailed animal-style shapes. Depending on your plush model, we help align the nose size, color, and locking method to ensure stability during sewing and assembly, as well as compliance with safety requirements for various markets.

Key Rings & Hanging Parts

For mini plush, keychains, and promotional plush items, metal and PVC-based key rings are frequently used. Options include standard O-rings, lobster clasps, ball chains, and reinforced hanging loops. We help you choose the right structure based on durability expectations and intended usage.

Apparel Accessories

Apparel-style add-ons—such as bows, neckties, ribbons, miniature clothing, lace trims, and tiny props—enhance branding and visual identity. These additions require proper stitching positions and reinforced attachment methods to ensure durability during handling and transport.

Internal Functional Components

Internal components like squeakers, rattle beads, voice modules, magnets, crinkle paper, and LED boxes add interactive value to plush designs. We evaluate placement, safety housing, and wiring feasibility to ensure these features integrate smoothly into mass production.

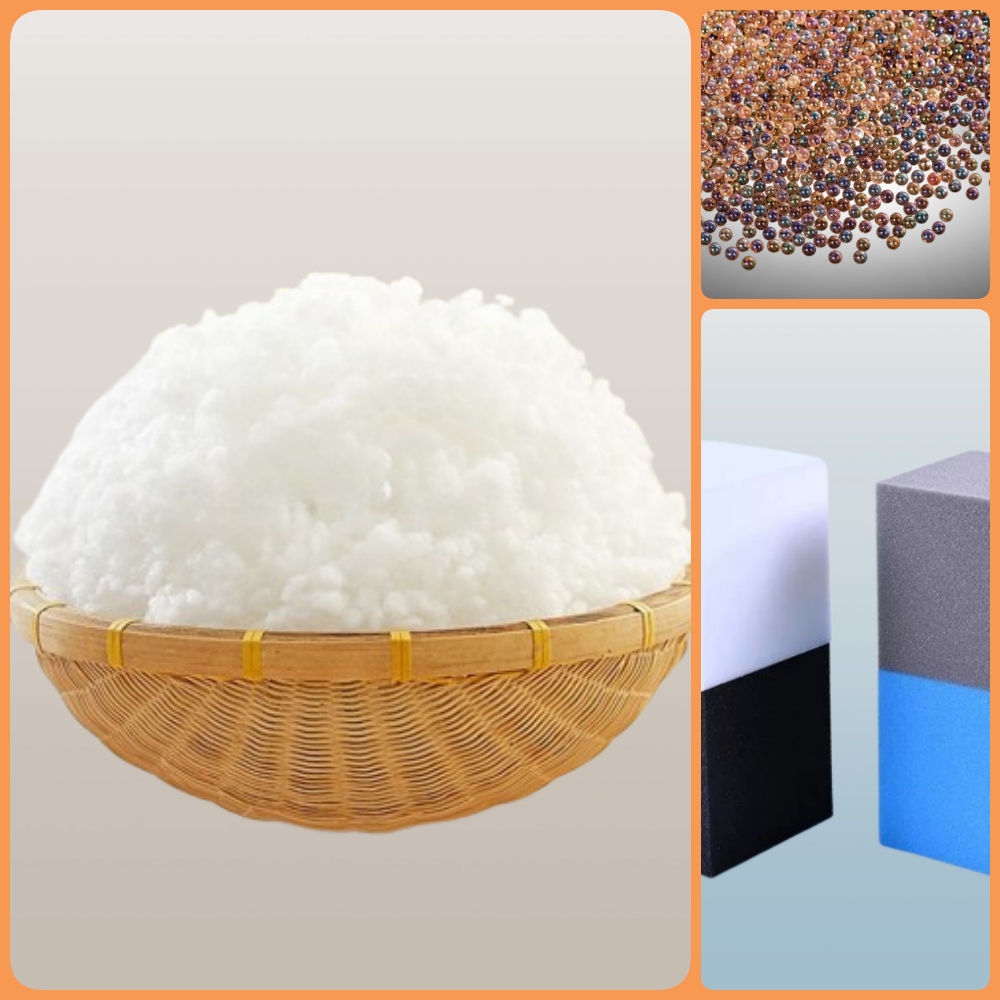

Stuffing & Inner Materials

Though not visible externally, stuffing quality plays a major role in plush firmness, durability, and shape retention. Common options include PP cotton (polyester fiberfill), memory foam fragments, microbeads, and weighted pellets. We recommend the appropriate filling type based on softness requirements, size, and structural needs of your plush design.

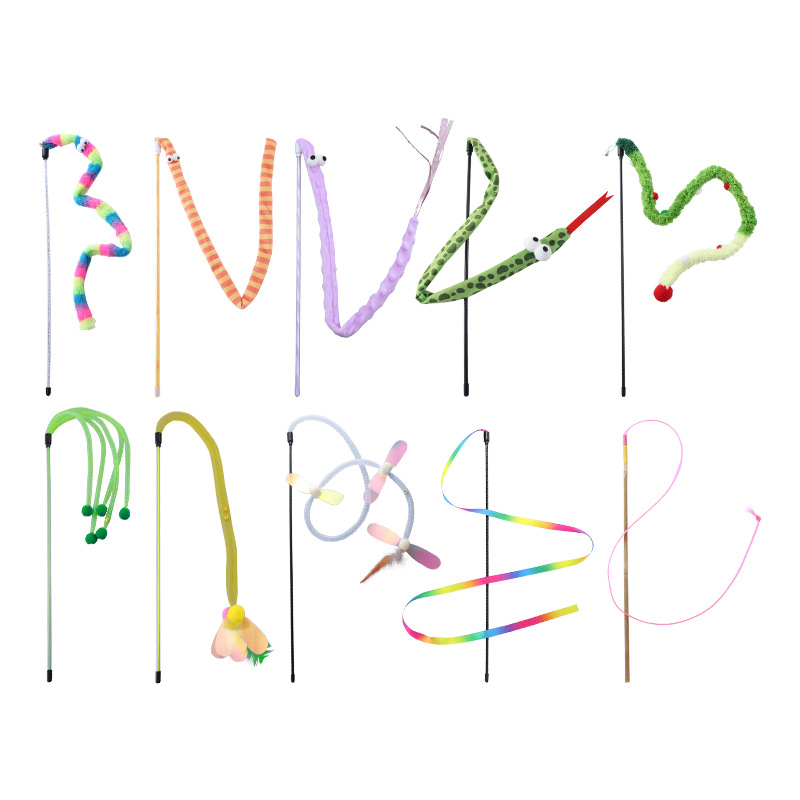

Pet Plush Toy Customization

Pet plush toys require different production standards compared with regular plush items. For brands developing chew-friendly or interactive pet products, we offer material and construction options specifically adapted for pets’ play behavior. Key features include the use of reinforced fabrics, secure stitching methods, and pet-safe internal components to improve durability and safety during use. We also support custom shapes designed for tugging, fetching, or gentle chewing, along with branding elements suitable for pet categories.

Custom Plush Toy Process

Our structured development process ensures your plush concept moves smoothly from idea to finished product. Each step focuses on clarity, accuracy, and efficient communication to keep your project on track.

Step 1: Project Inquiry

Share your concept details, and we’ll prepare an initial estimate with lead time and development notes.

Step 2: Design Confirmation

We review fabric options, dimensions, colors, and sketches to confirm all technical elements before sampling.

Step 3: Pattern & Structure Setup

Our team begins pattern drafting and builds the internal structure layout to form the foundation of your plush model.

Step 4: First Trial Sample

A rough sample is created to confirm proportions and shaping before adding embroidery, printing, or accessories.

Step 5: Detailed Sample Build

We produce a refined version with full features so you can assess the overall look and construction quality.

Step 6: Revisions & Adjustments

Based on your feedback, we revise the sample. Multiple adjustment rounds are available until the design meets expectations.

Step 7: Final Sample Preview

High-quality images and videos are provided to review details, expression, and craftsmanship from every angle.

Step 8: Physical Sample Approval

A physical unit is shipped for hands-on evaluation, allowing you to confirm quality before mass production.

Step 9: Production & Shipment

Once approved, bulk manufacturing begins. After final QC checks, your order is packed and dispatched according to your shipping method.

FAQ — Custom Plush Toy Development

What is a Custom Plush Toy?

A custom plush toy is a fully tailor-made product created to match your brand concept, design specifications, or promotional needs. Built through structured plush development and professional fabrication methods, each item is produced using selected materials and production standards suitable for bulk orders.

Can I personalize my plush design?

Yes. You can customize shape, colors, fabrics, facial features, accessories, packaging, and more. We support full personalization for private-label plush collections.

How do I make my own plush toy?

Send us your sketches, reference images, or a physical sample. Our team will assist with construction planning, pattern development, and sample creation to turn your concept into a production-ready plush.

What is the minimum order quantity for custom plush toys?

Our standard MOQ depends on the size and complexity of the design, but most orders begin at 100–500 units per style. Mixed SKUs can be combined when materials are shared.

How long does it take to produce custom plush toys from design to delivery?

The full cycle—design confirmation, sampling, revisions, and mass production—typically ranges from 25 to 45 days, depending on complexity and quantity.

How do you guarantee the quality and safety of custom plush toys?

We use certified materials, standardized production controls, and multi-stage inspection checkpoints. Safety requirements can be aligned with your destination market upon request.

What design files do you need to start customizing?

We accept sketches, 2D drawings, reference photos, or 3D models. Even simple drafts are fine—our development team will refine the details and create a usable structure.

Can I have an NDA signed before sharing my designs?

Absolutely. We can sign your NDA or provide our standard confidentiality agreement to protect your design rights.

Do you provide customized packaging?

Yes. Options include hang tags, back cards, polybags, printed boxes, or retail-ready packaging depending on your market channel.

Can you assist with shipping arrangements?

We offer support with international freight options such as air express, LCL, and FCL shipments. You can also ship through your own forwarder.

Do you offer warehousing or dropshipping services?

We do not provide dropshipping, but scheduled shipment and temporary storage solutions can be arranged for bulk clients if needed.

No. 122, West Houjie Avenue, Dongguan City, Guangdong Province, China,523960

Whatsapp:+86-13712576306

Tel:+86-13712576306

Email:zoe@wehaotoys.com

No. 122, West Houjie Avenue, Dongguan City, Guangdong Province, China,523960

Whatsapp:+86-13712576306

Tel:+86-13712576306

Email:zoe@wehaotoys.com